Add to Cart

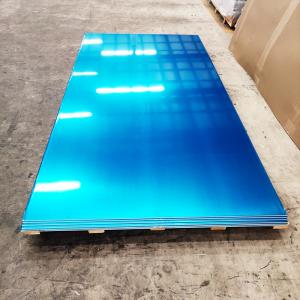

Polished Aluminum Sheet 5052 5754 5083 Mirror Finish Anodised

Product Description:

Aluminium mirror reflectors very smooth surface like real mirror, but high strength. Excellent weatherproof and sound resistance. Superior impact resistance, Lightweight and easy to maintain. Surface treatment: polished,anodized,mill finishing.

| Thickness | 0.2mm-600mm |

| Width | 20mm-2650mm |

| Length | As customer's requirements |

| Temper | O, T4,T6, T651, T7451 |

| Features | 1) Easy installation 2) High strength 3) Low in costs 4) Durable 5) Nice appearance 6) Anti oxidation |

| Application | 1) building and construction 2) decoration 3) curtain wall 4) Shelter 5) oil tank 6) mould |

| Surface | Flat every pieces covered with PE film |

| Packing | Export standard wooden pallets (as per requirements) |

| Payment Terms | 30% T/T in advance as deposit,70% balance against the B/L copy or 100% irrevocable L/C at sight |

| Remark | Specific requirement of alloy grade,temper or specification can be discussed at your request |

Mechanical Property:

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Zr | Other | Al | ||

| Single | Total | |||||||||||||

| 5A05 | 50 | 0.5 | 0.1 | 0.30~0.6 | 3.2~3.8 | — | — | 0.2 | — | — | — | 0 | 0.1 | Rem |

| 5B05 | 0.4 | 0.4 | 0.2 | 0.20~0.6 | 4.7~5.7 | — | — | — | Si+Fe:0.6 | 0.15 | — | 0.05 | 0.1 | Rem |

| 5A06 | 0.4 | 0.4 | 0.1 | 0.50~0.8 | 5.8~6.8 | — | — | 0.2 | Be:0.0001~0.005② | 0.02~0.10 | — | 0.05 | 0.1 | Rem |

| 5B06 | 0.4 | 0.4 | 0.1 | 0.50~0.8 | 5.8~6.8 | — | — | 0.2 | Be:0.0001~0.005② | 0.10~0.30 | — | 0.05 | 0.1 | Rem |

| 5A12 | 0.3 | 0.3 | 0.05 | 0.40~0.8 | 8.3~9.6 | — | 0.1 | 0.2 | Be:0.005 Sb:0.004~0.05 | 0.05~0.15 | — | 0.05 | 0.1 | Rem |

| 5A13 | 0.3 | 0.3 | 0.05 | 0.40~0.8 | 9.2~10.5 | — | 0.1 | 0.2 | Be:0.005 Sb:0.004~0.05 | 0.05~0.15 | — | 0.05 | 0.1 | Rem |

| 5A30 | Si+Fe:0.40 | 0.1 | 0.50~1.0 | 4.7~5.5 | — | — | 0.25 | Cr:0.05~0.20 | 0.03~0.15 | — | 0.05 | 0.1 | Rem | |

| 5A33 | 0.35 | 0.35 | 0.1 | 0.1 | 6.0~7.5 | — | — | 0.50~1.5 | Be:0.0005~0.005② | 0.05~0.15 | 0.10~0.30 | 0.05 | 0.1 | Rem |

| 5A41 | 0.4 | 0.4 | 0.1 | 0.30~0.6 | 6.0~7.0 | — | — | 0.2 | — | 0.02~0.10 | — | 0.05 | 0.1 | Rem |

| 5A43 | 0.4 | 0.4 | 0.1 | 0.15~0.40 | 0.6~1.4 | — | — | — | — | 0.15 | — | 0.05 | 0.15 | Rem |

| 5A66 | 0.005 | 0.01 | 0.005 | — | 1.5~2.0 | — | — | — | — | — | — | 0 | 0.01 | Rem |

| 5005 | 0.3 | 0.7 | 0.2 | 0.2 | 0.50~1.1 | 0.1 | — | 0.25 | — | — | — | 0.05 | 0.15 | Rem |

| 5019 | 0.4 | 0.5 | 0.1 | 0.10~0.6 | 4.5~5.6 | 0.2 | — | 0.2 | Mn+Cr:0.10~0.6 | 0.2 | — | 0.05 | 0.15 | Rem |

| 5050 | 0.4 | 0.7 | 0.2 | 0.1 | 1.1~1.8 | 0.1 | — | 0.25 | — | — | — | 0.05 | 0.15 | Rem |

| 5251 | 0.4 | 0.5 | 0.15 | 0.10~0.50 | 1.7~2.4 | 0.15 | — | 0.15 | — | 0.15 | — | 0.05 | 0.15 | Rem |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2~2.8 | 0.15~0.35 | — | 0.1 | — | — | — | 0.05 | 0.15 | Rem |

| 5154 | 0.5 | 0.4 | 0.1 | 0.1 | 3.1~3.9 | 0.15~0.35 | — | 0.2 | ① | 0.2 | — | 0.05 | 0.15 | Rem |

| 5154A | 0.5 | 0.5 | 0.1 | 0.5 | 3.1~3.9 | 0.25 | — | 0.2 | ① Mn+Cr:0.10~0.50 | 0.2 | — | 0.05 | 0.15 | Rem |

| 5454 | 0.25 | 0.4 | 0.1 | 0.50~1.0 | 2.4~3.0 | 0.05~0.20 | — | 0.25 | — | 0.2 | — | 0.05 | 0.15 | Rem |

| 5554 | 0.25 | 0.4 | 0.1 | 0.50~1.0 | 2.4~3.0 | 0.05~0.20 | — | 0.25 | ① | 0.05~0.20 | — | 0.05 | 0.15 | Rem |

| 5754 | 0.4 | 0.4 | 0.1 | 0.5 | 2.6~3.6 | 0.3 | — | 0.2 | Mn+Cr:0.10~0.6 | 0.15 | — | 0.05 | 0.15 | Rem |

| 5056 | 0.3 | 0.4 | 0.1 | 0.05~0.20 | 4.55.6 | 0.05~0.20 | — | 0.1 | — | — | — | 0 | 0.15 | Rem |

| 5356 | 0.25 | 0.4 | 0.1 | 0.05~0.20 | 4.5~5.5 | 0.05~0.20 | — | 0.1 | ① | 0.06~0.20 | — | 0.05 | 0.15 | Rem |

| 5456 | 0.25 | 0.4 | 0.1 | 0.50~1.0 | 4.7~5.5 | 0.05~0.20 | — | 0.25 | — | 0.2 | — | 0.05 | 0.15 | Rem |

| 5082 | 0.2 | 0.35 | 0.15 | 0.15 | 4.0~5.0 | 0.15 | — | 0.25 | — | 0.1 | — | 0.05 | 0.15 | Rem |

| 5182 | 0.2 | 0.35 | 0.15 | 0.20~0.50 | 4.0~5.0 | 0.1 | — | 0.25 | — | 0.1 | — | 0.05 | 0.15 | Rem |

| 5083 | 0.4 | 0.4 | 0.1 | 0.40~1.0 | 4.0~4.9 | 0.05~0.25 | — | 0.25 | — | 0.15 | — | 0.05 | 0.15 | Rem |

| 5183 | 0.4 | 0.4 | 0.01 | 0.50~1.0 | 4.3~5.2 | 0.05~0.25 | — | 0.25 | ① | 0.15 | — | 0.05 | 0.15 | Rem |

| 5086 | 0.4 | 0.5 | 0.1 | 0.20~0.7 | 3.5~4.5 | 0.05~0.25 | — | 0.25 | — | 0.15 | — | 0.05 | 0.15 | Rem |

Product Details:

Certification:

Packaging & Shipping:

FAQ:

Q1: ARE YOU FACTORY OR TRADER?

A1: Sylaith Special Steel is a cold rolling manufacturer of magnetic stainless steel coil since 2009. We've gained our Export Right and become an integrated company of industry and trade in order to satisfy buyer's multi-request on different material and products.

Q2: HOW TO GET A SAMPLE?

A2: FREE samples are available for your checking and testing. And to get free samples, you need to send us you detailed receiving address (including post code) and your DHL/FedEx/UPS account for collecting samples, courier cost will be paid in your side.

Q3: HOW TO VISIT YOUR FACTORY?

A3: Most of the main cities have flights to Shanghai; you can take flight to Shanghai Putong/Hongqiao International Airport.

If you come from Hongkong, it will take 2 hours by flight (every day 5 flight around noon time).